In 2022, we covered printing technologies, each with unique processes and benefits, used to print the wide range of products offered by 4over. The best print technology for a project depends on the quality, quantity, material, and how the print will be used. The number of finished printed products needed (quantity) and how quickly they are needed (turnaround time) greatly influence the pricing and, ultimately, the chosen printing technology. After you identify your customer’s need and use case, you can match it to the best product set and print technology.

The 4over team uses the best print technology for each product to ensure the best mix of functionality, visual impact, quality, and cost. Let’s recap the three print technologies spotlighted this year: digital electrophotography (EP), offset lithography, and screen printing.

Digital Electrophotography

Digital EP uses an electrostatically charged metal drum to receive small particles of colored toner that are transferred to the substrate before the drum is cleaned for the next cycle. That means each image can be different from the next, which is ideal for any printing where variable data is required, like direct mail or personalized invitations. EP print quality can rival offset lithography but is better suited for smaller quantities due to costs and turnaround times.

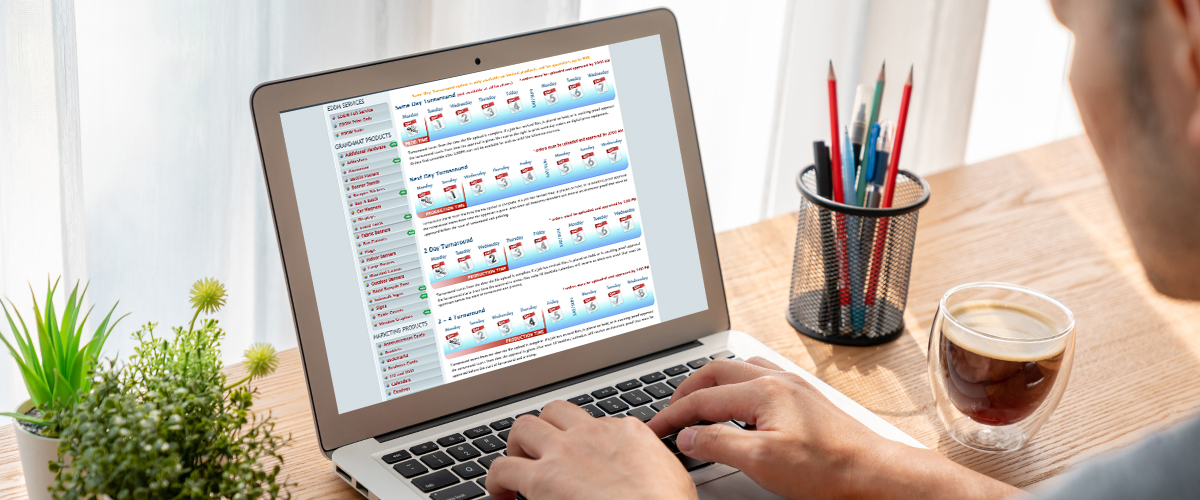

| |

Electrophotography |

Offset Lithography |

Screen Printing |

| Benefits |

- Lower quantities

- Near offset print quality

- Fast turnaround

- Variable data printing

- In-line finishing

- Specialty colors

- Enhancement options, including coatings, varnishes, and foil

|

- Higher quantities

- Low cost per page

- High image quality

- Specialty substrates

- Specialty colors

- Enhancement options, including coatings, varnishes, and foil

|

- Lower quantities

- Range of materials beyond paper

- Single to multi-color printing

- Durable

|

| Products |

|

|

|

Offset Lithography

Offset lithography, commonly shorted to just offset or litho, is based on the fact that oil (in the inks) and water do not mix. Imaged areas of the metal printing plate receive the oil-based ink and transfer it to the paper. Offset printing is still the industry’s workhorse due to the range of materials it can print on and its efficiency, particularly for higher quantities. Offset is best used for run lengths at least in the thousands since additional processes, like plate making, are required compared to digital printing.

Screen Printing

Screen printing pushes ink through a stretched mesh screen onto the material below, leaving an image that sits on top of the substrate. T-shirts are often screen printed. The process can be used on a wide variety of materials, like fabric feather signs or coroplast yard signs, and is durable enough to withstand fading from UV light, weather, and other adverse conditions.

Your clients are unaware and probably unconcerned about the different available printing technologies. A quality product delivered on time is their primary concern. As their trusted sales consultant, understanding the product specifications and appropriate printing methods available is where you can provide great value. Knowing that the best output for a screen-printed coroplast sign comes from a simplified design using fewer, less detailed graphics and larger type helps ensure a great outcome for your client. Similarly, the client’s design may call for very thick (24-point) paper for a quantity of a few hundred, which will increase the costs because it cannot run on most digital EP equipment. You can suggest a different paper suitable for EP printing to save cost, come in on budget, and meet their marketing goals.

As you wrap up this year, it’s a great time to audit your customer accounts and look for opportunities. Perhaps there are more opportunities to offer complimentary products to the ones already being purchased, like adding direct mail to their promotional products for better engagement and responses. Maybe they can consolidate their volumes from this year into fewer, less costly orders for next year.